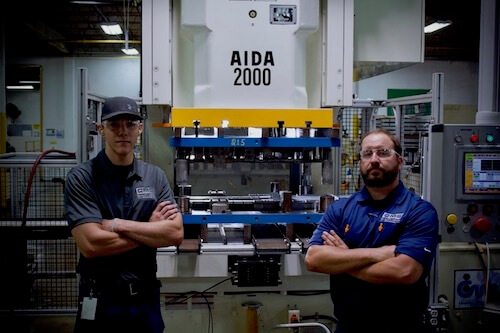

QMS Achieving Nearly 50% Efficiency Improvement on 200 Ton AIDA Servo Press

December 1, 2020

AIDA-America November 2020 Newsletter

Based upon information provided by Stephen Serling of Quality Metal Stamping, a world class metal stamping / fabrication facility and full service custom metal working solutions provider, the company continues to innovate and produce cost effective products for its customers. The fourth-generation family owned and operated business located in Henderson, TN recently invested in a 200 ton AIDA direct drive gap frame servo press, model DSF-C1-2000A, to help it do just that. Its next generation A Series press delivers the latest technology with AIDA’s exclusive Allen-Bradley control and several other enhancements.

Through its strategic partnership with AIDA, the Quality Metal Stamping Team has already achieved nearly a 50% efficiency improvement on parts moved from a mechanical press over to their new AIDA servo press. They’ve done so by taking advantage of the servo press’s complete programmability and optimizing high volume parts to run in pendulum mode, achieving production rates of 110+ spm. Stephen Serling notes that “Quality Metal Stamping is committed to continue to invest in the latest metal forming technology, and our partnership with AIDA will continue to be essential to our future growth.”